Engineers often use metal domes in electronic applications. However, a lesser-known use case for metal domes is as a pressure switch. As a result, metal domes are an overlooked solution for air or water pressure switches. Still, metal domes can be a cost-effective and easy-to-use alternative for engineers designing such devices.

What is a Pressure Switch? And, How to Incorporate Metal Domes

A pressure switch, also known as a differential pressure switch, is an electro-mechanical device that can recognize a difference in pressure between two points. These devices create an electrical connection when it reaches a certain threshold, most typically by air or water. The switch makes an electrical contact on either rise or fall from a certain preset level.

The most common pressure switch uses a pre-adjusted spring to sense the volume difference. Then, you can use it to make a contact change for an increase or decrease in pressure.

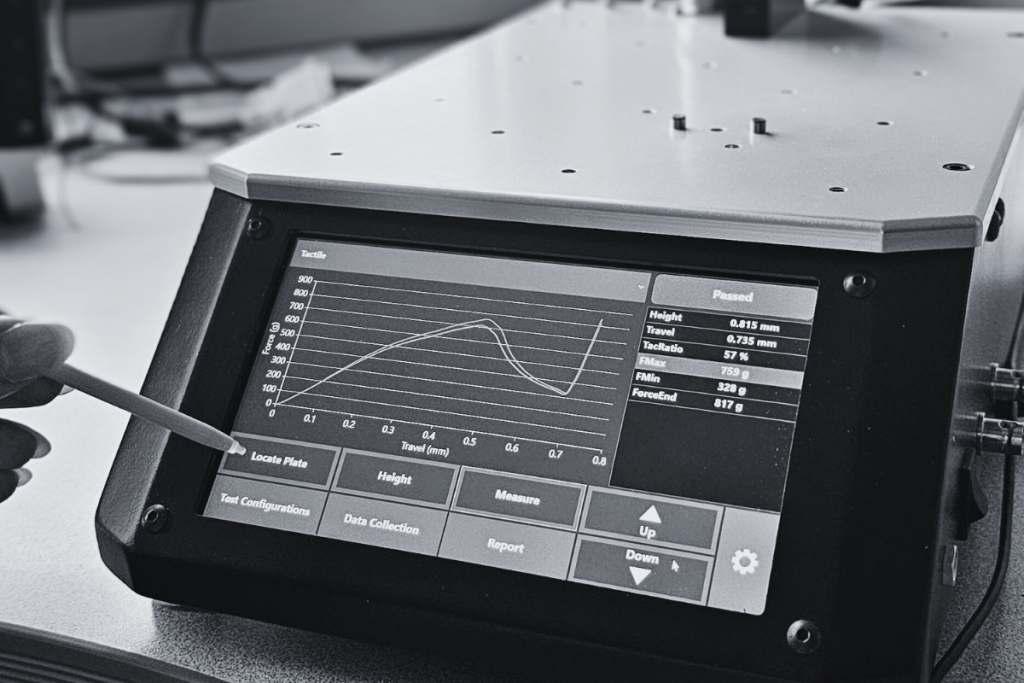

Alternatively, you can use a tactile metal dome to sense the desired force of a pressure switch application. When the micro-switch is triggered, the dome’s pretension directly correlates to the air or water pressure actuating the switch, making an electric contact. When the pressure drops, the metal dome resets to its original state.

Types of Switch Contact

Pressure switches usually have two different types of contact: normally open or normally closed. You can use both to make a contact change based on an increase or decrease in pressure.

When using a metal dome as normally open, the dome is mounted and curved away from the PCB contact pad. It will remain open until enough pressure can close it. Air or water pressure applied to the top of the dome pushes the dome down until it encounters the PCB and closes the switch.

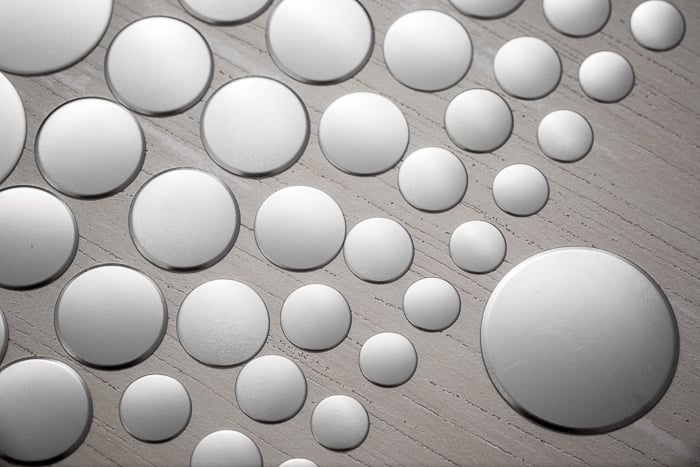

Snaptron custom designs and manufactures a variety of round metal domes that reliably and accurately work for these kinds of devices, specifically with limited space. Round domes, custom-designed to go bi-stable, meaning the state of a dome exhibits two stable conditions, can be used as normally open pressure switches. However, they can also function as normally closed pressure switches depending on your needs.

REA Technologies Pressure Switch Solution

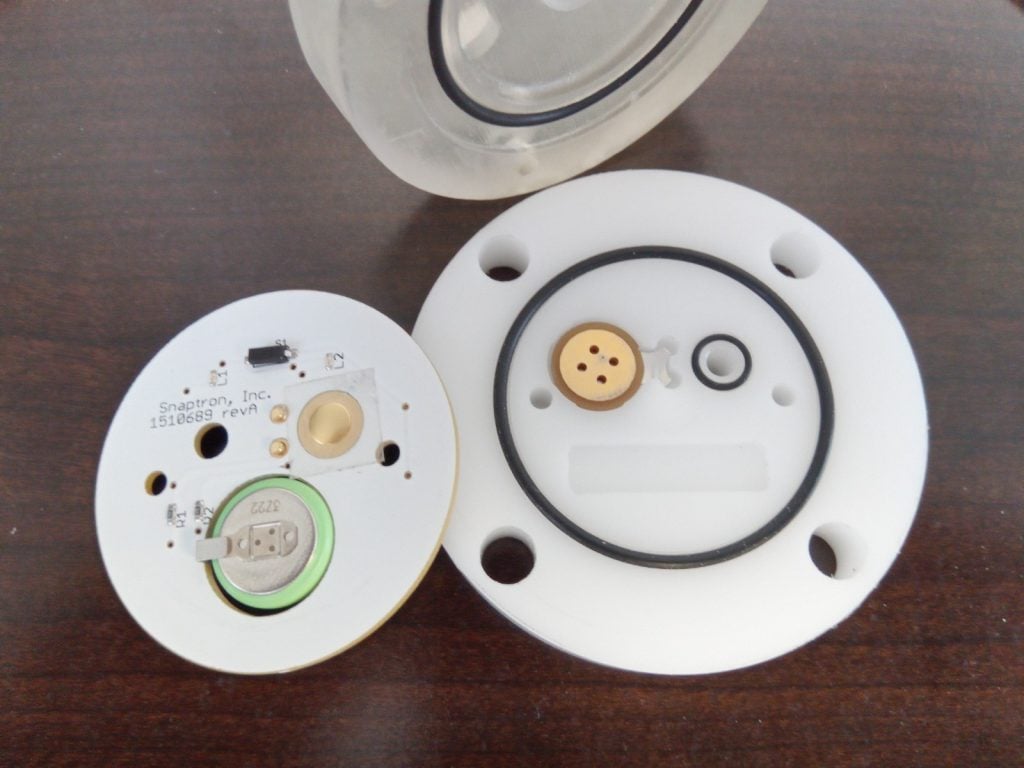

REA Technologies partnered with Snaptron to research a novel design for a normally closed differential pressure switch. This version requires only two components, a stainless-steel dome soldered to a circular PCB board. The dome is mounted, curved toward, and in contact with the PCB for this unique configuration. The small round dome is flanged and designed to be fully soldered down to support and seal the switch assembly. REA Technologies can also make it incorporate gold-to-gold contacts.

This switch works when either air or water force is applied, pushing the dome away from the PCB’s contact pad and opening the electrical switch. It maintains electrical contact until enough pressure is applied to open the switch. Once the pressure decreases, the metal dome resets to its normally closed state.

The REA Technologies option is reliable and capable of hundreds of thousands of cycles. Therefore, it would be a desirable choice for remotely monitoring pressure containers and pipelines. Additionally, it has a very small, accurate pressure threshold. As a result, you can use various pressure switch applications across many different industries such as aerospace, defense, marine, automotive, or energy.

While metal domes are best known for being used as components in electronic user interface applications, engineers can uniquely and reliably use them as a pressure switch. In addition, they are cost-effective and easy to implement into designs. Whether you prefer a normally open or normally closed version, using metal domes as a pressure switch is an innovative, consistent option when space is limited and accurate function is crucial.

Contact a Snaptron sales representative today to learn more about our pressure switch solutions.